The easiest, most foolproof way to build a relatively complex project is by first making a printed circuit board (PCB) . If you have the circuit pattern ( usually printed in an article or available on a website) you are far ahead of the game. There are various ways to create circuits boards.

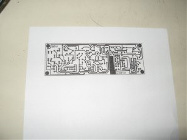

One of the currently popular methods consists of printing the circuit pattern onto photographic paper and ironing it onto a clean piece of copper clad board. This must be done with a laser printer. I recently acquired an old HP laser printer and this has become my main method. Now do this at your own risk. Don’t blame me if it goes wrong. There are several web pages explaining this and some videos on YouTube.

This is what I do. First of all, you have to use ink-jet glossy photographic paper. I use an HP laser-jet 1012. Do a test before, because your printer may not work as well as the old HP.

Basically you print the circuit board pattern. Then you use a regular clothes iron set at the highest heat to iron the pattern onto a clean copper clad board cut to the size that you need. You need to apply even pressure. You may have to experiment a few times. Once you think it’s ready, soak the board in warm water for a while. Twenty minutes or so. Then peel the photo-paper off the board. You should be left with the circuit pattern on the copper board. Read below on who to etch it. If there are some lines that are not copied onto the board, you can use an etch resistant pen to make corrections. Remember that the toner and etch-resistant ink must protect the copper from being dissolved. This will become your circuit.

Here is the non-laser printer method that I used to use.

You will need to get some copper clad board. Single-sided should do in most cases. I buy large sheets and cut them to size.

I use a hand-held jigsaw or scissors. You’ll need some etching solution, like ferric chloride. Be careful as this will eat away the copper and other metals as well as permanently stain bathroom fixtures. You’ll need a plastic container in which to do your etching. Get your own. Your wife or Mom will not appreciate you staining their kitchen containers. You need plastic or glass containers because ferric chloride is an acid that will dissolve metal. It will also stain your skin. Get yourselves a pair of rubber gloves and a plastic apron or long coat. You’ll need to work in a well-ventilated area. The fumes are rather unpleasant and likely unhealthy. I do my etching in the bathroom because if there ever was an accident there would be less damage. Please read up on etching copper boards with ferric chloride. This article concentrates on the method, not the safety matters. You must use your brains. Only you are responsible for yourself.

First I copy (or scan) the circuit pattern, making sure that the size is correct. Sometimes a circuit pattern has been printed half size to save space. Other times it is not to scale but sometimes there is a ruler printed to show the dimensions. It is usually VERY important to respect the scale. The main reason is that IC chips, relays etc have fixed footprints usually in .1 of inch increments. If your holes are off, you’ll never be able to fit the parts in. When I have to resize a circuit pattern I use an IC socket to test the pin spacing before I start drilling. Print the pattern on plain paper when in doubt and check if the pattern is the correct size. Sometimes a mirror image of the pattern is printed. This is an easy fix with Photoshop or some other graphic editing software.

Other times it is not to scale but sometimes there is a ruler printed to show the dimensions. It is usually VERY important to respect the scale. The main reason is that IC chips, relays etc have fixed footprints usually in .1 of inch increments. If your holes are off, you’ll never be able to fit the parts in. When I have to resize a circuit pattern I use an IC socket to test the pin spacing before I start drilling. Print the pattern on plain paper when in doubt and check if the pattern is the correct size. Sometimes a mirror image of the pattern is printed. This is an easy fix with Photoshop or some other graphic editing software.

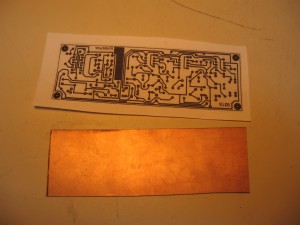

Once the pattern is printed I cut around the pattern leaving an extra inch on all sides. I then cut a piece of copper board to match the circuit. I tape the circuit pattern to the copper board. Then I drill all the holes using the pattern as a guide.

One note on drill bits. Usually, holes are between 1/64 to 1/32 of an inch. You can buy special tapered bits with thicker ends that will lock into the drill press chuck. Check on eBay. I found a great set of bits at an even better price from China.

You could try to use a hand drill or a Dremel but a drill press is more efficient and a lot faster. I now use a Dremel with a Dremel drill press.

After all the holes are drilled, I remove the paper pattern and clean the copper with steel wool. It must be totally clean before you etch it. Do not touch the copper again.

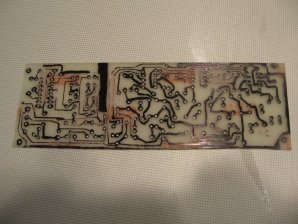

Now the fun part. Using an etch resistant pen I draw small black circles around all the holes. Then I draw the lines as seen on the circuit pattern.

When I am 100% certain that I have not made any mistakes, I let the ink dry. An etch resistant pen is available in most electronic shops or Radio Shack stores. They come in different sizes, so you may want to buy a few different line sizes. A permanent marker may work but I haven’t done enough testing. The idea is to eat (etch) away all the copper from the board leaving only the copper-covered by the pen. This copper is used to connect the components. I move into the bathroom. I put my rubber gloves and old work coat on to protect my skin and clothing.

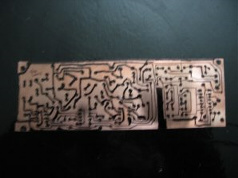

I put the board into a plastic rectangle container with sides about 4 ” high. It’s been said that heat will speed the process but I have never been at ease with the idea of heating the ferric chloride acid. I have developed another method. Prior the pouring the ferric chloride acid over the board I run the hot water in the sink. When the water is super hot, I half fill the sink with it. I dip the acid-filled container in the water and hold it so that the hot water will indirectly heat up the ferric chloride acid. Make sure that the sink water does not pour into the plastic container. I pour enough ferric chloride into the container to cover the board and a little bit extra. Don’t forget to put the cap back on the acid. It will take about 15 minutes to etch the board so be patient. Rock the plastic container gently back and forth so that the acid washes over the board often. This will speed up the process. Soon you will start to see only the pattern. There may be some leftover spots of copper so again be patient.

Some of the basic tools

The Soldapult, solder vacuüm. Pliers,cutters, strippers.

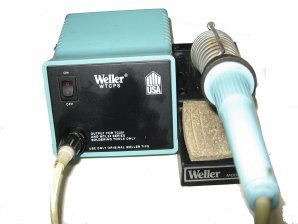

A soldering station is a great investment.

As soon as you see no more copper you must stop the process.

I usually empty the sink and run cold water into the plastic container to dilute the acid. Keep rinsing with cold water and make sure that there is no residue in the sink.

Next, let the board dry. You may pat away the extra water with a paper towel. When the board is dry, clean away the etch-resistant ink with steel wool. Don’t press the steel wool too hard against the board. You will be left with just the copper pattern. Now it’s time to place your components. Be extra careful of orientation of certain components i.e. polarized capacitors, diodes, transistors and ICs. Flip the board over and solder the components. Never use too much solder.

When all the board mount components are soldered into place it’s time to connect the outboard components.